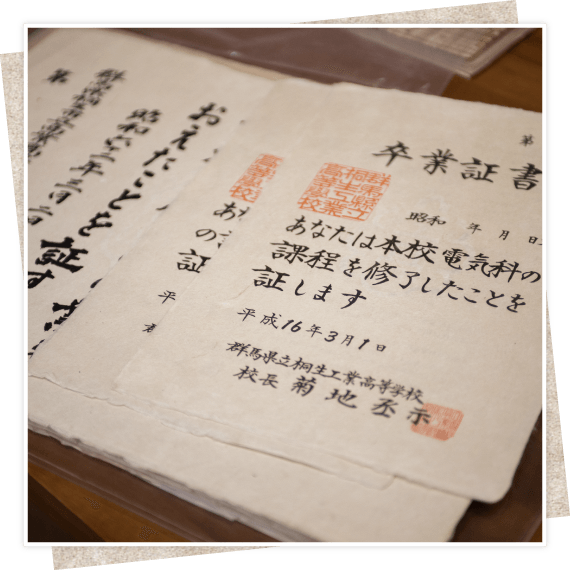

Kiryu Washi

In Gunma prefecture, there is only one manufacturer that can produce Kiryu Washi and just as the name suggests, it`s in Kiryu City. It`s the only source where there are still engineers who know the technology of producing Washi.

Starting the process with the growing of the mulberry bud(kuwa no kozo) and finishing the product, all being done handmade, implies a lot of manual work. Washi, in Japan, it was used for drawing paper, shouji, or printed paper.

Simmering(first boil)

After one year of growing the paper mulberry plant(kō zo), the fiber is thicker than 1 cm and the skin of the dried shrubs, can be used for paper making.

The craftsman will prepare some bunches of 1 m cut trees(shrubs), bundle them in pieces and simmer or steam them for about one hour, thus making the skin to be easily peeled and to facilitate stripping bark from the wood( while still being hot). In fact, the craftsman will scrape it off with a knife and he will repeat the process 4-5 times in a day during the peak period.

It seems more efficient and quicker to use caustic soda in the process but it will also dissolve and drain the lye(aku) of the plant. To obtain a good quality, to take advantage of the goodness of the Japanese paper it is needed to leave the lye. As a commitment, the process used instead(boiling with soda ash – sodium carbonate) will be longer, will take time and effort. Also, the craftsman will not use adhesive for gathering the paper but instead will use a process hydrogen bonds in which long fibers intricately intertwine.

Dust collecting and cleaning (scars checking)

It`s the most time and effort consuming process in the production of the Japanese paper, but it`s also one of the most important parts. It`s the essence for producing a good quality of Washi. It is said that skipping this important but thorough part, there would be no meaning of producing Washi.

In this process, small rubbish and dust, would be manually removed one by one in the same time.

Crushing phase(beat up)

This is the technique of breaking and peeling off the dust from the paper mulberry skin, brushed in the previously process. The craftsman will use for spanking a Japanese traditional sword, similar to a naginata sword, but without sharpness: beat-strike-beat-strike.

Kneading phase(paper making)

After the beating process made by hand or with a mallet will obtain a loosened texture, so the craftsman will dehydrate and dry up the product. Succeeding, he will mix water, stock and mucus (neri) extracted from the roots of Tororoaoi(a kind of okra※) and knead it. The fibers have to be dispersed one by one so they will be cut each with a stick of bamboo.

※Tororoaoi has a very good condition in winter that means it has to be stored after harvest for a year before use.

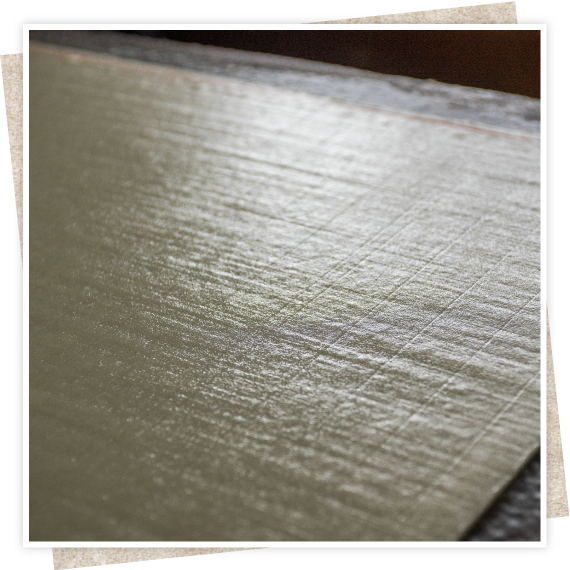

Spreading out thin(paper making)

This is the mechanism of pouring the stock on the boat-shaped papermaking tank. The way to wash and store the product, it will depend on the purpose of the paper. (post cards, business cards etc)

It is also important to control the water temperature, and this will be adjusted by pouring ice, depending on the season.

Pressing

This is the action of applying pressure to squeeze the water.

Drying

In this operation, the craftsman will strip and peel each piece and stick it on a drying board. Then dry it with a brush.